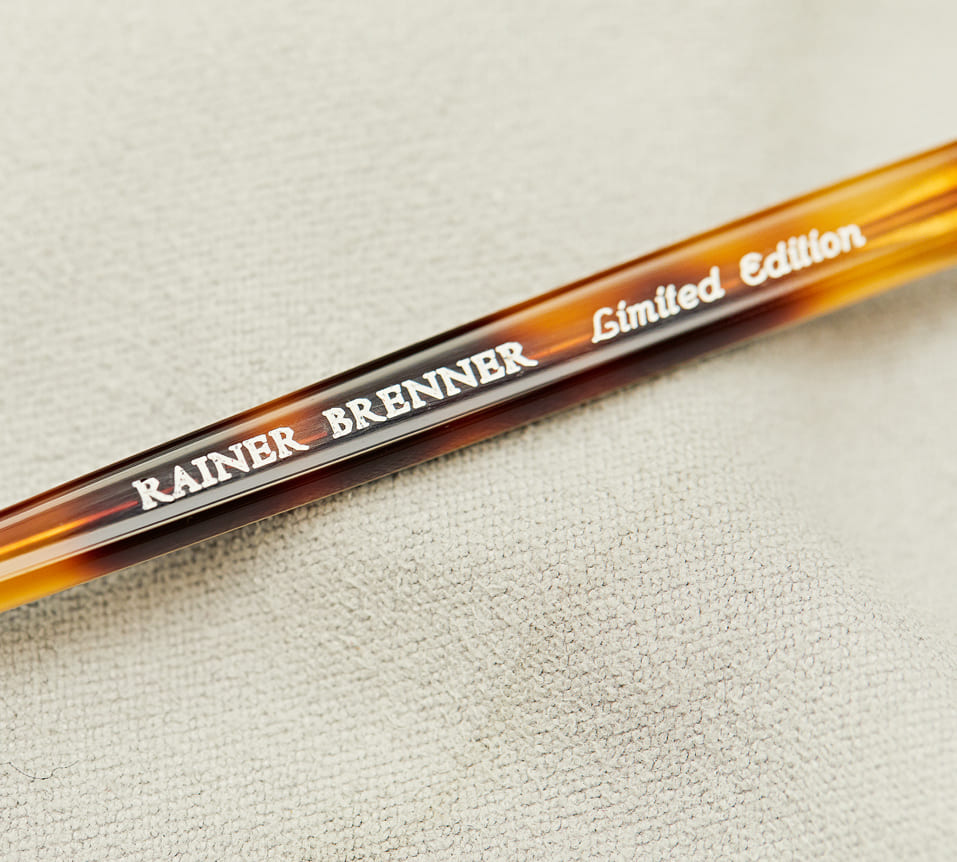

RAINER BRENNER eyewear is always special. This is partly due to the elaborate production process, that has a lot of hand-made elements. Have a look at the most important steps during the manufacturing process.

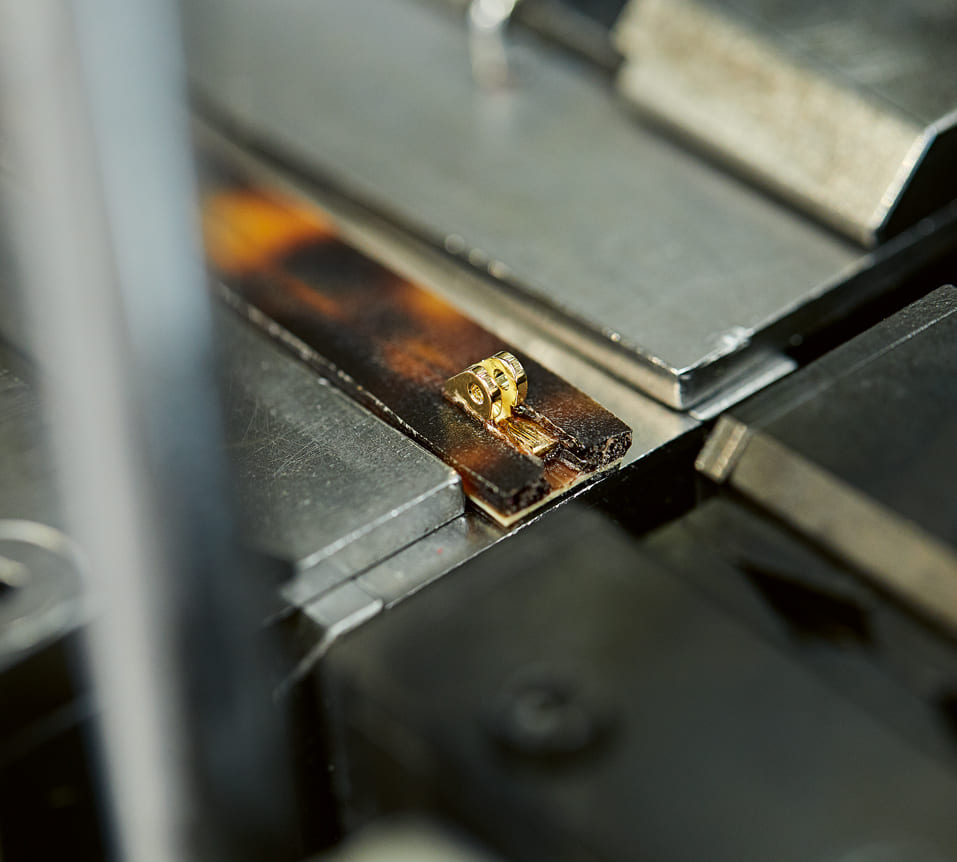

Cutting the blanks

During the first step, the blanks are milled from the high-end synthetic material with a CNC machine, precisely to the thousandth of a millimeter. At this point, the final shape of the frame is already clearly discernible.

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Rainer Brenner Augenoptik GmbH

Goethestraße 24

60313 Frankfurt am Main

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00

Mo – Fr 10.00-19.00 Sa 10.00-18.00